Engineering Technology

The OBHE process ensures with its unique technology an effective use of Caprolactam without waste, equipment deposits and environmental impacts.

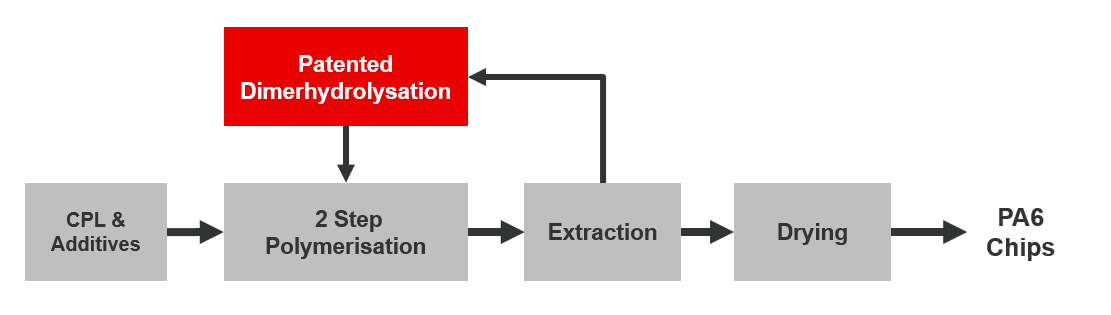

Our patented Dimerhydrolysation process enables the production of chips for high quality applications and elevating the entire value-added chain of the investment to a higher quality level.

The chips will be produced in a process of two step Polymerisation.

The design of Prepolymerisation and Postcondensation ensures the full consumption of additives as well as a very uniform reaction time until the equilibrium of the Polymerisation process.

By this and as well in combination with our patented Dimerhydrolysation process the very uniform product quality can be guaranteed.

During the extraction, the remaining monomer is extracted from the PA6 chips, the solid/liquid countercurrent extraction process is carefully controlled by temperature circuits.

In the drying heated nitrogen is removing the humidity from the PA6 chips in two different heating zones. After drying, the chips are cooled indirectly by cooling water. After cooling the chips are conveyed with nitrogen into silos and finally bagged.

According to your requirements OBHE tailors the overall design of the PA6 polymerisation plant for customers final application

Starting with textile grade, film grade and engineering plastics as well as technical applications, our product portfolio covers the entire range of possible applications

With OBHE rich experience in chemical plant design you cooperate with one competent partner of responsibility for the overall performance of your PA6 solution.